Gestión de operaciones y vía--en (6)

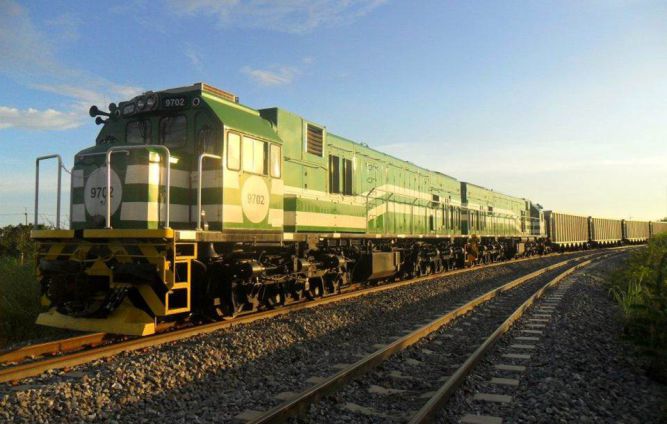

In recent years Fenoco S.A. has shown a significant advance in the maintenance service and in its operation, so the multinationals that exploit coal in the region of Province of Cesar, can transport this mineral, all this has been achieved thanks to the strengthening and improvement of the techniques through which the trains are mobilized on the railway line.

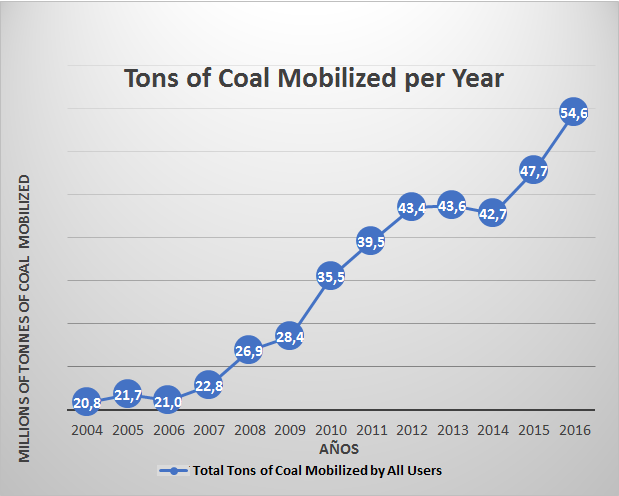

Following is a record by years of the tons of coal transported by the multinationals over the past twelve years:

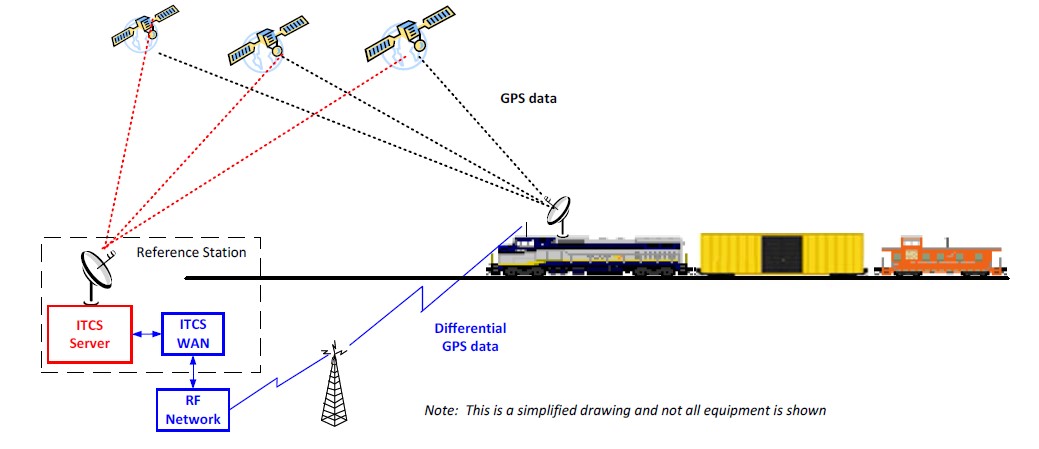

For the support of the ITCS system of the railway operation in general and of the different maintenance areas of Fenoco, there are different communication systems for the transmission of voice and data, based on different platforms and standards considered cutting edge technologies.

Tetra System

It is a standard defined by ETSI (European Institute of Telecommunications Standards) as a mobile digital radio system that unifies several alternative interfaces. This system is made up of several devices that allow voice and data communication between all actors of the railway operation, CTF, train masters, maintenance personnel, etc.

As end devices for the user, portable radios, mobile radios, base radios and RTPS are available. The management of the system is done through a redundant central node together with the different base stations installed along the railway track, which store and process the calls or data generated daily in the operation. In addition, all voice processes are stored in a recorder that is part of the management node. These records are used to follow-up and control of the communication protocols and investigation in case of incidents.

Fig. 1 Tetra Topology

WIFI y GPS System

This system is used for locating and recognizing trains from the beginning of the route to their arrival at their destination, constantly updating and checking information with the devices located in each railway station.

Transport network

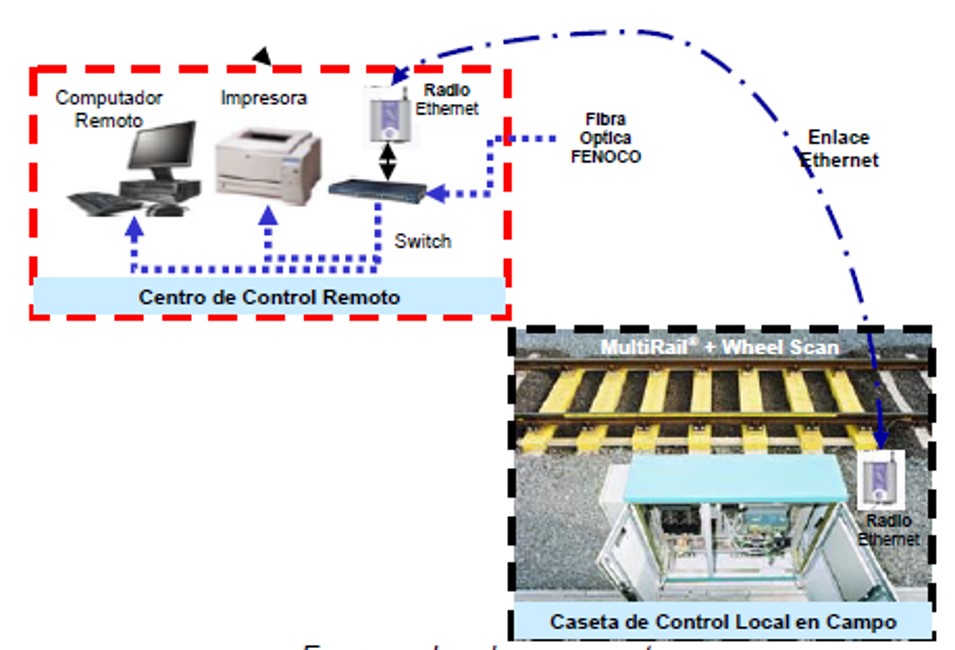

As a transportation network, Fenoco installed more than 200 km of fiber optic in the section between La Loma (Cesar) and Ciénaga (Magdalena), which works in a redundant manner by having a second fiber backing path , management and traffic is carried out through redundant layer 2 switches installed in the railway stations, changeover booths and Data Center, resulting in a network in rings to avoid interruption in data transmission.

You can know data such as the accuracy of the dynamic weighing for the entire train, accuracy of dynamic weighing per wagon related to the full scale range, accuracy of the dynamic weighing per bogie, maximum allowable speed variation during the weighing process.

MULTIRAIL Dynamic Weighing Scales

Click the pic to enlarge.

Accuracy of the Scale According to Speed

|

Precision of the dynamic weighing for the entire train: |

|

|

|

±0.5 at a speed of 10 - 30 km/h |

|

|

±1.0 at a speed of 30 - 50 km/h |

|

|

±1.5 at a speed of 50 - 70 km/h |

|

|

|

|

Precision of the dynamic weighing per wagon, related to the total range of the scale: |

|

|

|

±1.0 at a speed of 10 - 30 km/h |

|

|

±1.5 at a speed of 30 - 50 km/h |

|

|

±2.5 at a speed of 50 - 70 km/h |

|

|

|

|

Precision of the dynamic weighing per boogie: |

|

|

|

±2.0 at a speed of 10 - 30 km/h |

|

|

±3.0 at a speed of 30 - 50 km/h |

|

|

±4.0 at a speed of 50 - 70 km/h |

|

|

|

|

Precision of the dynamic weighing per axle |

|

|

|

±4.0 at a speed of 10 - 30 km/h |

|

|

±5.0 at a speed of 30 - 50 km/h |

|

|

|

|

|

|

|

Maximum speed variation allowed during the weighing process: |

|

|

|

V= ± 3km/h |

|

|

|

|

Calibration method: |

Dynamic Through a reference wagon, which has been previously weighed on a static scale by the client. |

Location and Communication Scale -CCO

Location of the scales:

La Loma: PK 749 +250.

Ciénaga: PK 930 + 270.

The operation of the railway section concessioned to Fenoco is controlled through ITCS, which is a centralized traffic control system with virtual signaling and positive control of train speed, the main components and functionalities are described in the items described below.